Sewage Treatment Filter Ball

- Product Item : 01

- Category: Sewage Treatment Filter Ball

- Color: White, Black, Yellow, Pink

- Appearance: Globular

- Type: Oil/Water Separation agent

- Package: 700g/7kg/10kg/25kg/customized

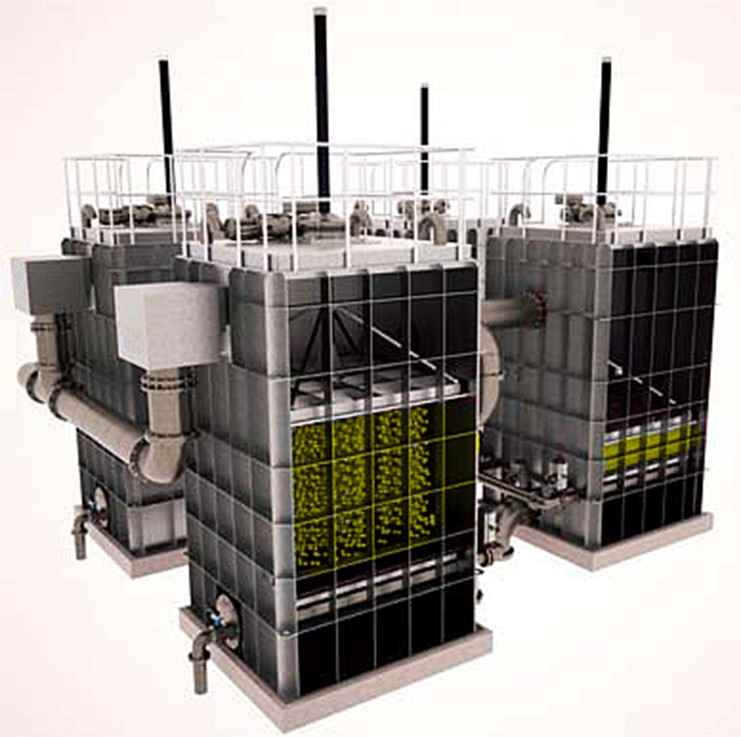

About Sewage Treatment Filter Ball

What Are filter fiber ball, and How Do They Work?

Filters are an essential component of any wastewater treatment system. Without them, water would simply flow through the treatment steps without being purified. There are many filtration products available for a wastewater pump, but one of the latest and greatest is the filter fiber ball system.

How do filter fiber ball work?

The filter fiber ball uses a 30-inch-deep media bed made of 1.25-inch fiber balls constructed of high-grade, compressible polymer. As water flows over the fiber balls, the balls compress, trapping solid particles before they can enter the next wastewater treatment step. The filter uses influent and air scrubbing to wash the balls after filtration, easily cleaning the balls for reuse.

Common applications

Because they’re modular in design, filter fiber ball can be used in any size system to filter out whatever solids are present. They can be used in everything from well water treatment systems to remove solids and iron to wastewater treatment plants for phosphorus removal. Drinking water plants as well as oil and gas companies can benefit from switching to a filter fiber ball.

What are the advantages of filter fiber ball?

filter fiber ball wouldn’t be such a popular wastewater treatment choice if they didn’t often a number of advantages over other filtration products.

A few reasons wastewater companies switch to filter fiber ball system:

● Superior filtration rate: The main reason to upgrade to a filter fiber ball is its filtration rate. While most filters are rated at three gallons per minute per square foot, filter fiber ball system have a rate of 30 gallons per minute per square foot and remove solids up to four micrometers in diameter. When you consider filter fiber ball do their job 10 times faster than other filters, making the switch is a no-brainer.

● Higher compression percentage: The standard compression percentage for an average filter is approximately 30 percent. Due to the filter fiber ball design, it achieves a compression rate of up to 40 percent, allowing it to filter out more solids than an ordinary filter.

● Longer lifespan: filter fiber ball have a lifespan of anywhere from 10 to 20 years and require no replacement in between. This long lifespan reduces a treatment plant’s overhead costs while eliminating all sorts of maintenance requirements.

● Filtration adjustment: Because it is a compressible filtration system, filter fiber ball allow operators to adjust the media porosity for the in-fluent characteristics. So, a filter fiber ball system is essentially a one-stop shop for all a treatment plant’s filtration needs.

Features

| Item | Specification |

| Material | Polyester, Polyethylene |

| Color | White, Black, Yellow, Pink, Customized |

| Diamter | 30, 40, 50mm, Customized |

| Wear resistance | Excellent |

| Filtering velocity | 20-50m/h |

| Flush water time | 10-20min |

| Gas flushing strength | 3m3/min.m2 |

| Flush water consumption | 3% |

| Suspended matter removal rate | 90%~96% |

| Processing capacity | 8-20/m3/h |

| Filling density | 60-80kg/m3 |

| Transport Package |

700g Carton/Bag; 2.7kg Carton; 10/25kg Bag etc |

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: George

Mobile:+86 152 6553 7961

Tel:+86 571 8796 1150

Whatsapp:+86 152 6553 7961

Email:yb@ybtex.com.cn

Add:Room 1206, Building 1, Zhongsha Golden plaza, No. 228 Shangsha Road, Xiasha Street, Qiantang District, Hangzhou City, Zhejiang Province